Mack MP7 EPA04 Diesel Engine Service Shop Manual

$19.99

Covers: Mack MP7 EPA04 Diesel Engine (2004-2006)

- MP7-325E

- MP7-355E

- MP7-405E

- MP7-345C

- MP7-365C

- MP7-395C

- MP7-325M

- MP7-365M

- MP7-405M

Pages: 379

Format: PDF

Works with: Windows/Mac/Tablet

Notes: Searchable, printable, instant download

The MACK MP7 is a 700 CID (11.0L) engine with Delphi E3 unit injectors, a cooled EGR system and the new Holset Variable Geometry Turbocharger. The design conforms to EPA04 emissions. This shop manual covers all maintenance, repair and overhaul procedures for the Mack MP7 EPA04 engine. This manual covers in-chassis service and out-of-chassis overhaul procedures. View the shop manual on your computer/tablet or print off pages as needed.

Topics:

- Introduction

- About the Mack Mp7 Engine

- Mp7 Engine Model Identification

- Description and Operation

- Mp7 Engine Design Features

- Mp7 Engine Component Location Views

- Troubleshooting

- Engine Symptom Diagnosis

- Engine Checks and Inspections

- Camshaft Sensor and Harness Checks

- Compression Test

- Maintenance

- Lubrication System Maintenance

- Fuel Filter Replacement

- Cooling System Maintenance

- Drive Belt Replacement and Tensioning

- Engine Removal

- Engine Disassembly

- Cylinder Block Reconditioning

- Flywheel Bench Procedures

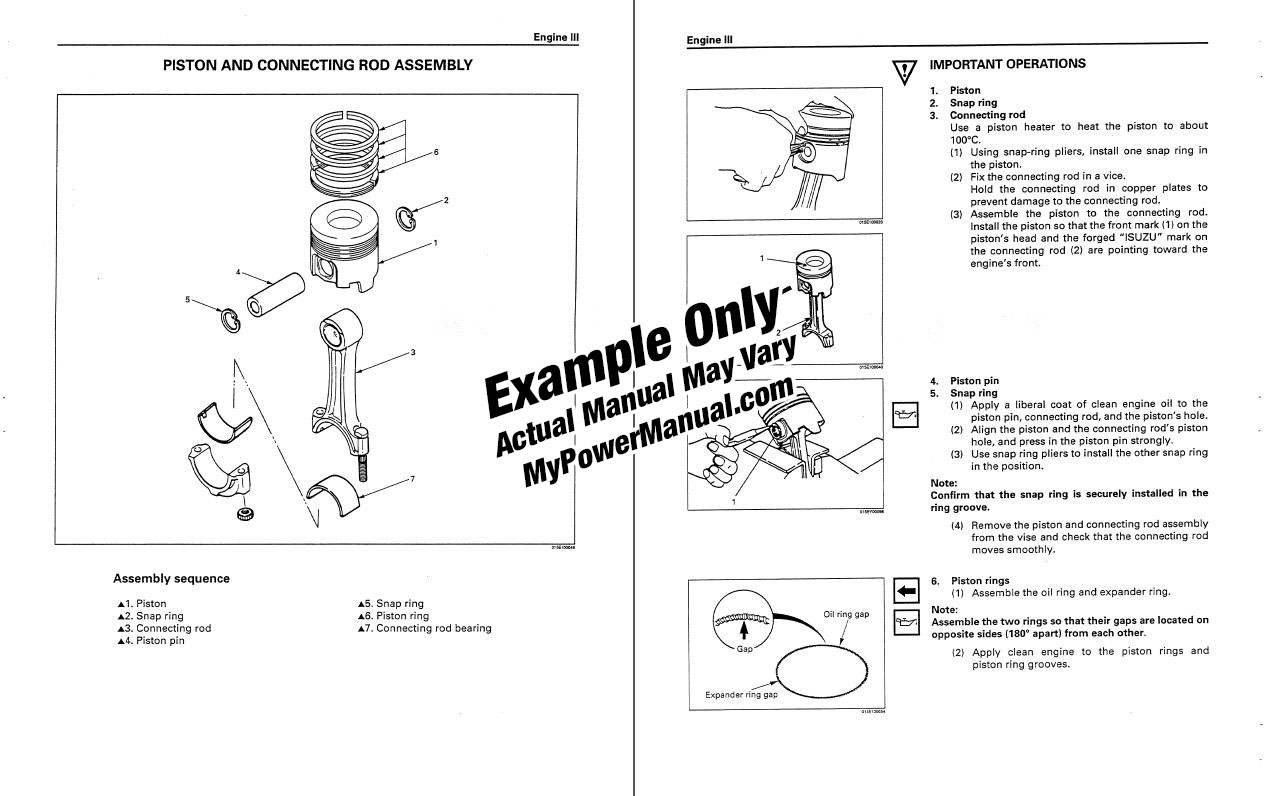

- Connecting Rod and Piston Bench Procedures

- Cylinder Head Overhaul

- Rocker Arm Shaft Bench Procedures

- Camshaft Bench Procedures

- Cooling System Components Bench Procedures

- Engine Reassembly

- Engine Installation

- In-chassis Part/component Procedures

- Oil Pump Replacement (in Chassis)

- Unit Injector Cleaning

- Injector Copper Sleeve Replacement

- Turbocharger Smart Remote Actuator (Sra) Replacement

- Valve Stem Height Measurement Procedure

- Valve Stem Seal Replacement

- Mp7 Engine Setup and Adjustment

- Engine Final Preparation and Operational Check

- Rebuilt Engine Run-in Procedures

- Mp7 Engine Mechanical Specifications

- Engine Gaskets, Lubricants and Sealants

- Schematic & Routing Diagrams

- Mp7 Engine System Schematics

- Wiring Diagram

- Special Tools & Equipment

- Mp7 Engine Service Tools

- Mp7 Engine Disassembled Views

- Index