Detroit Series 60 EPA98/04 Engine Service Manual

$24.99

Covers: Detroit Series 60 11.1L, 12.7L, 14L on-highway engines

- Diesel and Natural Gas

- With or without EGR

- 1987-2006, excludes EPA07 emissions (2007+)

Pages: 1,685

Format: PDF

File size: 20mb

Works with: Windows/Mac/Tablet

Notes: Bookmarked, searchable, printable, instant download

This PDF manual contains complete instructions on operation, adjustment (tune-up), preventive maintenance, and repair (including complete overhaul) for the Detroit Series 60 diesel and natural gas engines. This service manual was written primarily for mechanics servicing and overhauling the Series 60 engine. In this service manual you will find detailed Series 60 mechanical repair instructions and illustrations. View this service manual on your computer or print off page as needed. This manual is also referred to as the Workshop Manual or Repair Manual.

DDEC troubleshooting manuals sold separately

Topics:

General Information

- Clearance Of New Parts And Wear Limits

- The Four Cycle Principle For Diesel Engines

- Four Cycle Principle For Natural Gas Engines

- General Description

- General Specifications

- Engine Model, Serial Number And Option Label

- Replacing And Repairing

- Disassembly

- Cleaning

- Safety Precautions

- Engine Views

- Conversions

- Specifications

Engine

- Cylinder Block And Cylinder Liner

- Cylinder Head

- Valve And Injector Operating Mechanism

- Valves, Springs, Guides, Inserts, Seals And Rotators

- Engine Lifter Brackets

- Rocker Cover

- Crankshaft

- Crankshaft Oil Seals

- Crankshaft Main Bearings

- Gear Case Cover Pre-EGR and EGR

- Gear Case Pre-EGR and EGR

- Crankshaft Vibration Damper

- Crankshaft Pulley

- Flywheel

- Ring Gear

- Flywheel Housing

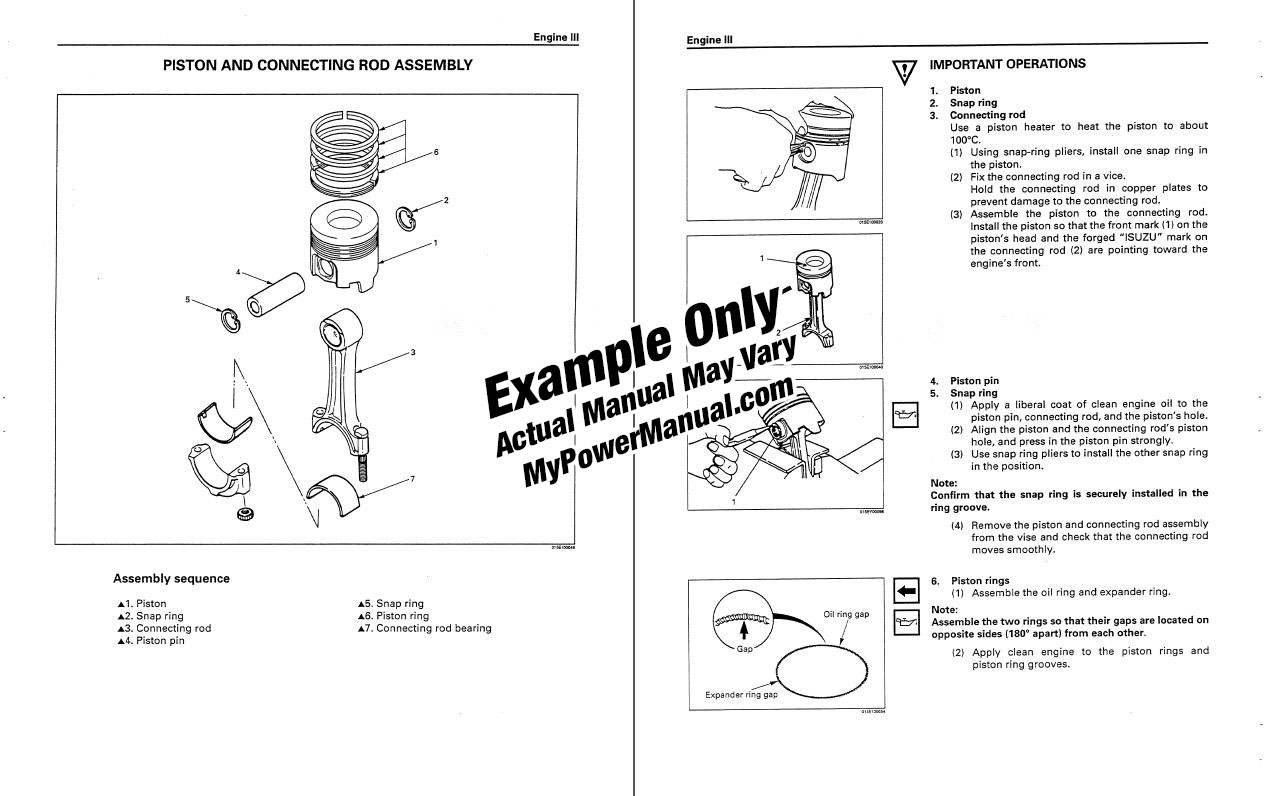

- Piston And Piston Ring

- One-piece Piston Assembly And Piston Ring

- Piston And Connecting Rod Assembly

- Connecting Rod

- Cylinder Liner

- Gear Train And Engine Timing

- Compact Gear Train And Engine Timing

- Camshaft Gear Assembly Series 60 (EGR) Model

- Thrust Plate Perimeter Seal

- Camshaft And Camshaft Bearing

- Camshaft Drive Gear

- Adjustable Idler Gear Assembly

- Adjustable Idler Gear Compact Gear Train

- Bull Gear And Camshaft Idler Gear For The Compact Gear Train

- Bull Gear And Camshaft Idler Gear Assembly

- Crankshaft Timing Gear And Timing Wheel

- Accessory Drive

- Jake Brake

Fuel System

- Diesel Fuel System Overview

- Vehicle Safety For The Natural Gas Engine

- N2 Electronic Unit Injector

- N2 Fuel Injector Tube And O-ring

- N3 Electronic Unit Injector

- N3 Fuel Injector Tube

- Fuel Pump With Separate Drive Shaft And Hub

- Fuel Pump With One-piece Drive Shaft And Hub Assembly

- Fuel Pump Drive

- Diesel Fuel Filters (Spin-on)

- Fuel Pro 380/380e Fuel Filter System

- Fuel Filter Type For The Series 60g Engine

- Assembly Fuel Filter And Water Separator

- Electronic Engine Control

- DDEC V Electronic Control Unit

- DDEC Iii/iv Electronic Control Module

- DDEC Ii Electronic Control Module

- DDEC I

- Programmable Read-only Memory (Prom) DDEC I

- Electronic Distributor Unit DDEC I

- Electronic Foot Pedal Assembly

- Turbo Speed Sensor (Tss)

- Turbo Boost Pressure Sensor

- Air Intake Pressure Sensor

- Oil Pressure Sensor

- Oil Temperature Sensor

- Air Temperature Sensor

- Air Temperature Sensor For High Pressure Fuel System

- Coolant Temperature Sensor

- Synchronous Reference Sensor Gear Case Mounted

- Synchronous Reference Sensor / Camshaft Position Sensor Camshaft Gear Cover Mounted

- Timing Reference Sensor

- Coolant Level Sensor

- Fuel Pressure Sensor

- Fuel Temperature Sensor

- Exhaust Gas Oxygen Sensor For Series 60g Engines

- Exhaust Temperature Sensor For The Series 60g Engines

Lubrication System

- Oil Pump

- Oil Pressure Regulator Valve

- Oil Pressure Relief Valve

- Oil Filter

- Oil Filter Adaptor

- Thermatic Oil Control Valve

- Oil Cooler

- Oil Level Dipstick Assembly

- Oil Pan

- Ventilating System

Cooling System

- Water Pump

- Thermostat

- Coolant Pressure Control Cap

- Engine Cooling Fan

- Coolant Filter And Conditioner

- Radiator

Air Intake System

- Air Cleaner

- Intake Manifold

- Closed Crankcase Breather For Series 60g Automotive Engines

- Turbocharger (Diesel)

- Turbocharger Series 60 Natural Gas (Automotive) Engine

- Recirculation Valve For Series 60g Automotive Engine

- Charge Air Cooler

- Throttle Actuator For The Series 60g Engine

- Air Dryer

Exhaust System

- Three-piece Exhaust Manifold

EGR Components

- Tube And Shell Bolted Flange EGR Cooler

- Hydraulic EGR Valve

- Delivery Pipe

- EGR Rate Measurement System

- DDEC IV/V Variable Pressure Output Device

Electrical Equipment

- Alternator

- Storage Battery

- Cranking Motor

- Tachometer Drive

- DDEC III/IV Engine Sensor Harness

- DDEC II Engine Sensor Harness

- Metri-pack 150 Series Connectors

- Micro-pack Series Connectors

- Weather Pack And Metri-pack 280 Series Connectors

- Connector Tools

- Splicing Guidelines

PTO

- Front/Rear PTO

Special Equipment

- Air Compressor (Vehicle Applications Only)

- Air Compressor Drive Hub

Operation And Verification

- Preparation For A First Time Start

- Starting

- Running

- Stopping

- Operating Conditions

- Series 60g Automotive Engine Operating Conditions

- Engine Run-in Instructions

Engine Tune-up

- Engine Tune-up Procedures

- Valve Lash, Injector Height (Timing) And Jake Brake Lash Adjustments

- Engine Tune-up Procedures For The Series 60g Engine

- Valve Lash For The Series 60g Engine

Preventive Maintenance & Storage

Ignition System

- Coil Over Plug Ignition System

- Ignition Coil Assembly

- Ignition Boot Assembly

- Igniter Module

- Igniter Module Bracket

- Ignition Coil Harness

- Spark Plugs

You may also like…

-

Detroit DDEC II Troubleshooting Manual & Wiring Diagram

$19.99 -

Detroit Diesel Series 60 Engine Parts Manual

$14.99 -

Detroit Diesel DDEC 3, DDEC 4 Single ECM Troubleshooting Manual

$24.99 -

Detroit Diesel DDEC I Troubleshooting Manual

$19.99 -

Detroit Series 60 DDEC V Troubleshooting Manual

$29.99 -

Detroit Diesel Series 60 EPA07 14.0L Engine Service Manual (LATEST)

$39.99