Detroit Series 60 Marine Diesel Engine Service Manual

$29.99

Covers: Detroit Series 60 Marine Diesel Engine

- 11.1L

- 12.7L

- 14.0L

- Pre-EPA07

Pages: 2,117

Format: PDF files

File size: 27mb

Features: Searchable, printable

Works with: Windows/Mac computers

This manual provides service and repair instructions for marine applications of the Detroit Series 60 diesel engine (with DDEC I, II, III/IV, V controls). In this service manual a basic overview of each major component and system along with recommendations for removal, cleaning, inspection, criteria for replacement, repair and installation and mechanical troubleshooting are included. View the service manual on your computer or print off pages as needed.

Includes Application and Installation Manual. DDEC electronic troubleshooting manuals & wiring diagrams sold separately.

Topics in the Detroit Series 60 Marine Diesel Engine Service Manual:

GENERAL INFORMATION

ENGINE

- CYLINDER BLOCK AND CYLINDER LINER

- CYLINDER HEAD

- VALVE AND INJECTOR OPERATING MECHANISM

- VALVES SPRINGS GUIDES INSERTS SEALS AND ROTATORS

- ENGINE LIFTER BRACKETS

- ROCKER COVER

- CRANKSHAFT

- CRANKSHAFT OIL SEALS

- CRANKSHAFT MAIN BEARINGS

- GEAR CASE COVER

- GEAR CASE

- CRANKSHAFT VIBRATION DAMPER

- CRANKSHAFT PULLEY

- FLYWHEEL

- RING GEAR

- FLYWHEEL HOUSING

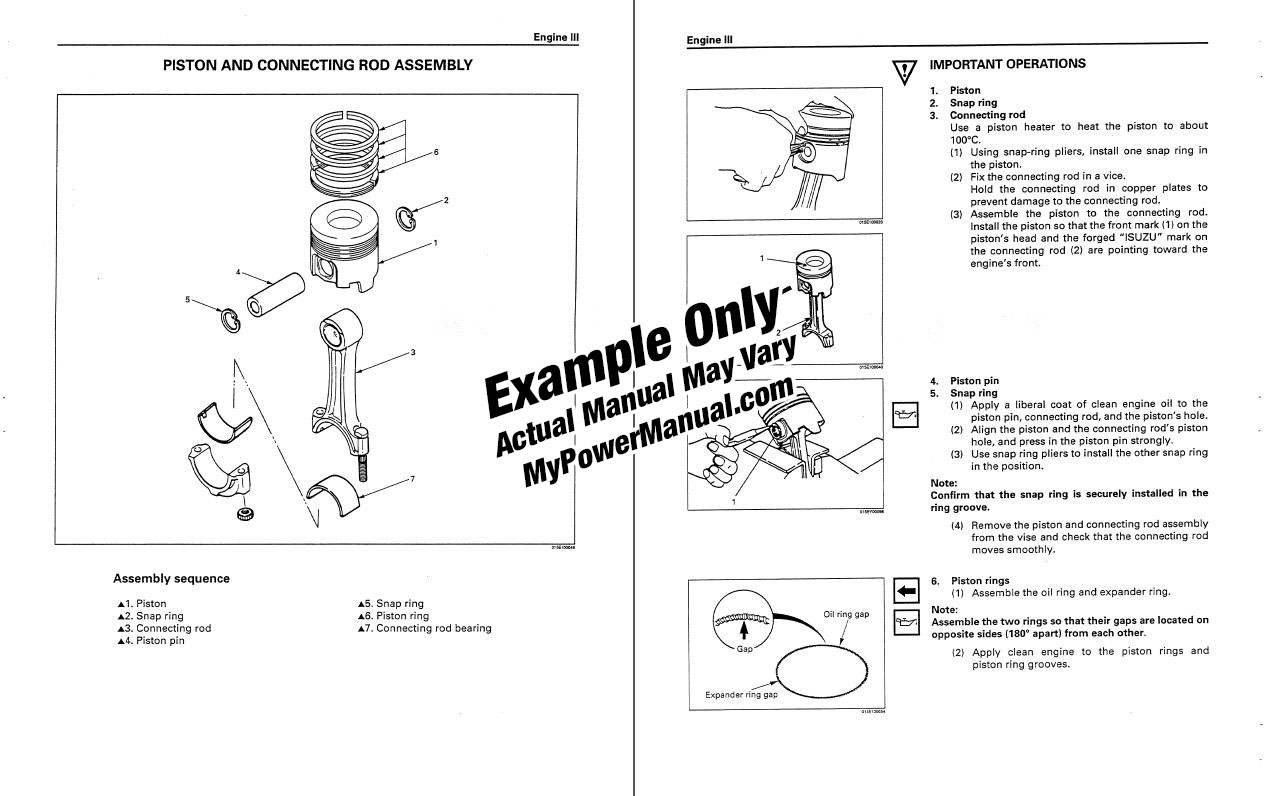

- PISTON AND PISTON RING

- FORGED STEEL ONE PIECE PISTON ASSEMBLY AND PISTON RING

- PISTON AND CONNECTING ROD ASSEMBLY

- CONNECTING ROD

- CYLINDER LINER

- GEAR TRAIN AND ENGINE TIMING

- THRUST PLATE PERIMETER SEAL

- CAMSHAFT AND CAMSHAFT BEARING

- CAMSHAFT DRIVE GEAR

- ADJUSTABLE IDLER GEAR ASSEMBLY

- BULL GEAR AND CAMSHAFT IDLER GEAR ASSEMBLY

- CRANKSHAFT TIMING GEAR AND TIMING WHEEL

- ACCESSORY DRIVE

- JAKE BRAKE

FUEL SYSTEM

- DIESEL

- NATURAL GAS

LUBRICATION SYSTEM

- OIL PUMP

- OIL PRESSURE REGULATOR VALVE

- OIL PRESSURE RELIEF VALVE

- OIL FILTER

- OIL FILTER ADAPTOR

- THERMATIC OIL CONTROL VALVE

- OIL COOLER 1991 AND LATER ENGINES

- OIL COOLER PRE-1991 ENGINES

- OIL LEVEL DIPSTICK ASSEMBLY

- OIL PAN

- VENTILATING SYSTEM

COOLING SYSTEM

- WATER PUMP GEAR CASE MOUNTED 1991 AND LATER GCM

- WATER PUMP FRONT MOUNTED FM

- CHARGE AIR COOLER RAW WATER PUMP KEELCOOLED

- COMMERCIAL MARINE

- THERMOSTAT

- COOLANT PRESSURE CONTROL CAP

- ENGINE COOLING FAN

- COOLANT FILTER AND CONDITIONER

- RADIATOR

- KEEL COOLING SYSTEM COMMERCIAL MARINE 4109

- HEAT EXCHANGER COOLING SYSTEM PLEASURE CRAFT MARINE

- HEAT EXCHANGER PLEASURE CRAFT MARINE

- JABSCO ENGINE COOLING RAW WATER PUMP MARINE

AIR INTAKE SYSTEM

- AIR CLEANER

- AIR SEPARATOR

- INTAKE MANIFOLD

- EXHAUST MANIFOLD

- TURBOCHARGER DIESEL

- TURBOCHARGER SERIES 60 GAS ENGINES GENSET

- TURBOCHARGER SERIES 60 NATURAL GAS AUTOMOTIVE ENGINE

- RECIRCULATION VALVE FOR SERIES 60G AUTOMOTIVE ENGINE

- CHARGE AIR COOLER

- THROTTLE ACTUATOR FOR THE SERIES 60G ENGINE

- AIR DRYER

ELECTRICAL EQUIPMENT

- BATTERY CHARGING ALTERNATOR

- STORAGE BATTERY

- CRANKING MOTOR

- TACHOMETER DRIVE

- DDEC IIIIV ENGINE SENSOR HARNESS

- DDEC II ENGINE SENSOR HARNESS

- METRIPACK 150 SERIES CONNECTORS

- MICROPACK SERIES CONNECTORS

- WEATHER PACK AND METRIPACK 280 SERIES CONNECTORS

- CONNECTOR TOOLS

- SPLICING GUIDELINES

PTO

AND MORE….