Detroit DD13, DD15, DD16 EPA07/10/GHG14 Engine Workshop Manual

$29.99

Covers: Detroit DD13, DD15, DD16 EPA 07/10/GHG14 Diesel Engine

Pages: 315

Format: PDF

File size: 44mb

Works with: Windows/Mac/Tablet

Notes: Bookmarked, searchable, printable, instant download

This manual contains engine-out mechanical workshop procedures, illustrations and specifications for the service and overhaul of Detroit DD13, DD15, DD16 EPA07, EPA10, GHG14 diesel engines. Sections generally cover description & operation, removal & installation, inspection & cleaning, disassembly & assembly and adjustment, where applicable.

Manuals for the fuel system, exhaust/aftertreatment/EGR system and troubleshooting are available separately, or purchase the complete service manual bundle for 2007-2016 engines and save.

Topics:

- Rocker Cover

- Camshaft and Rocker Shaft/Engine Brake Assembly

- Camshaft Housing

- Camshaft Timing

- Gear Train and Engine Timing

- Coolant Crossover Pipe

- DD15 and DD16 Water Manifold Assembly

- DD13 Exhaust Gas Recirculation Cooler – Water Manifold Assembly

- Cold Boost Pipe (Charge Air Pipe)

- Composite Cold Boost Pipe

- Air Intake Manifold

- DD13 Turbocharger

- DD13 Wastegate Solenoid

- GHG14 DD15 Wastegate Solenoid

- DD15 and DD16 Turbocharger

- DD15 and DD16 Axial Power Turbine

- DD15 and DD16 Axial Power Turbine Gear Box

- Cylinder Head

- Intake and Exhaust Valves and Valve Springs

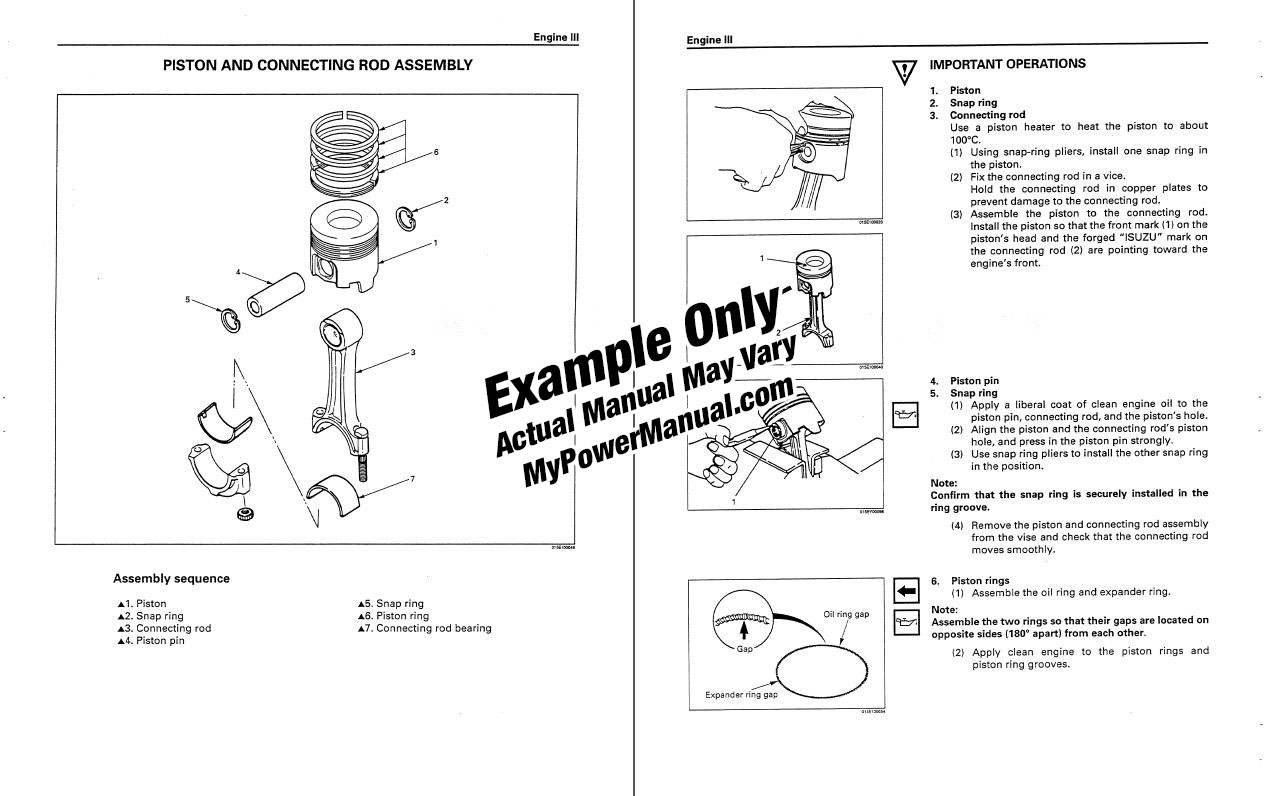

- Piston and Connecting Rod Assembly

- Cylinder Liner

- Crankshaft

- Crankshaft Oil Seals

- Lubrication System

- Oil Pan

- Oil Level/Temperature Sensor

- Oil Dipstick Tube

- Oil Pump, Oil Suction Manifold, and Oil Lines

- Crankcase Breather

- Oil Filter Replacement

- Oil Sample Valve

- Oil Filler Neck

- Oil Coolant Module

- Oil Cooler

- Oil Thermostat

- Priming the Lubrication System

- Cooling System

- Engine Water Pump

- Variable Speed Engine Water Pump

- Coolant Thermostat

- Coolant Filter

- Coolant Filter Service Module

- Coolant Inlet Elbow

- Flywheel, Ring Gear and Flywheel Housing

- Front Engine Mount/Radiator Support

- Vibration Damper

- Front Engine Cover

- Engine Lifter Brackets

- Belt Drive Tensioner System

- Poly-V-Belts

- Air Compressor

- Air Compressor Unloader Valve

- Cylinder Block

- Engine Wiring Harness

- Clutch

- Pilot Bearing