Caterpillar C16 7CZ Diesel Engine Complete Service Manual

$79.95

Covers: Caterpillar C16 Diesel Engine with serial prefix

- 7CZ

Pages: 1,751

Format: PDF files (zipped)

File size: 59mb

Compatibility: Windows/Mac computers

Notes: Bookmarked, searchable, printable, instant download

This 7-volume service manual set contains complete specifications, systems operation information, disassembly and assembly procedures, testing and adjusting instructions and troubleshooting steps for the Caterpillar C16 7CZ diesel engine. Additionally, the Cat C16 7CZ engine wiring diagrams are included in high resolution PDF format. This is a complete OEM reference for professional mechanics to service and repair the engine. View the manuals on your computer or print off pages as needed.

Please contact us with your engine serial number if you have compatibility questions.

Topics:

Engine Specifications

Engine Systems Operation

- General Information

- Electronic Control System Components

- Fuel System

- Air Inlet and Exhaust System

- Lubrication System

- Cooling System

- Basic Engine

- BrakeSaver

- Compression Brake

- Electrical System

Disassembly and Assembly

- Fuel Priming Pump – Remove and Install

- Fuel Filter Base

- Fuel Transfer Pump

- Electronic Unit Injector

- Turbocharger

- Exhaust Manifold

- Inlet and Exhaust Valves

- Engine Oil Filter Base

- Engine Oil Cooler

- Engine Oil Pump

- Water Pump

- Water Temperature Regulator

- Engine Support (Front)

- Flywheel

- Crankshaft Rear Seal

- Flywheel Housing

- Vibration Damper and Pulley

- Crankshaft Front Seal

- Front Cover

- Gear Group (Front)

- Housing (Front)

- Accessory Drive

- Valve Mechanism Cover

- Compression Brake

- Rocker Arm and Shaft

- Cylinder Head

- Camshaft

- Camshaft Gear

- Camshaft Bearings

- Engine Oil Pan

- Cylinder Liner

- Piston Cooling Jets

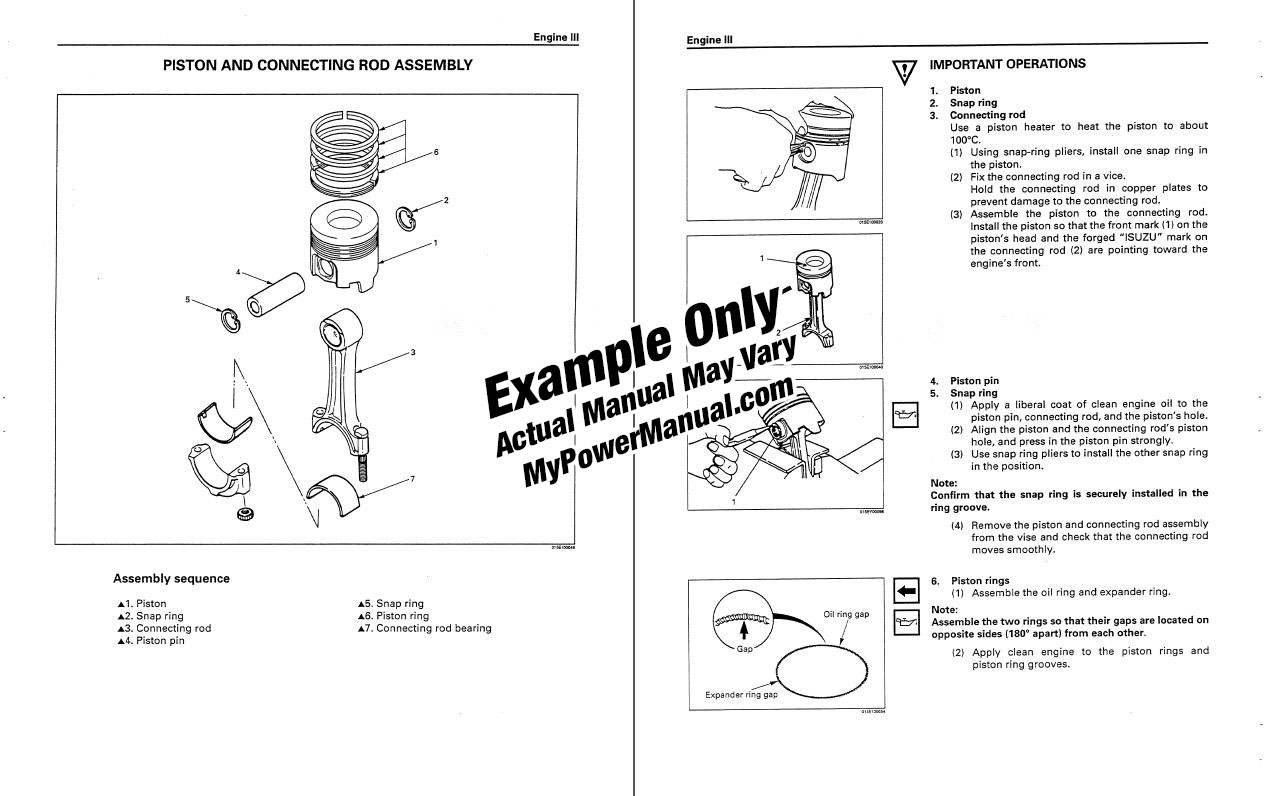

- Pistons and Connecting Rods

- Connecting Rod Bearings

- Crankshaft Main Bearings

- Crankshaft

- Bearing Clearance

- BrakeSaver

- BrakeSaver Engine Oil Pan

- BrakeSaver Engine Oil Pump

- BrakeSaver Control Valve

- Atmospheric Pressure Sensor

- Camshaft Position Sensor

- Crankshaft Position Sensor

- Coolant Temperature Sensor

- Engine Oil Pressure Sensor

- Fuel Temperature Sensor

- Boost Pressure Sensor

- Inlet Air Temperature Sensor

- Belt Tensioner

- Fan Drive

- Engine Control Module

- Electric Starting Motor

- Air Compressor

- Air Compressor Drive Gear

Testing and Adjusting

- Fuel System

- Air in Fuel

- Electronic Unit Injector

- Finding Top Center Position for No. 1 Piston

- Fuel Quality

- Fuel System – Prime

- Fuel System Pressure

- Gear Group (Front) – Time

- Air Inlet and Exhaust System – Inspect

- Turbocharger – Inspect

- Inlet Manifold Pressure

- Exhaust Temperature

- Aftercooler – Test

- Inlet Manifold Pressure

- Engine Crankcase Pressure (Blowby)

- Compression Test

- Engine Valve Lash – Inspect/Adjust

- Engine Oil Pressure Test

- Excessive Bearing Wear

- Excessive Engine Oil Consumption

- Increased Engine Oil Temperature

- Cooling System – Check

- Water Temperature Regulator

- Water Pump

- Piston Ring Groove

- Connecting Rod Bearings

- Main Bearings

- Cylinder Block

- Cylinder Liner Projection

- Flywheel

- Flywheel Housing

- Vibration Damper

- Jake Brake Compression Brake Adjustment

- Pacbrake Compression Brake Adjustment

- Control Valve (Compression Brake)

- Solenoid Valve (Compression Brake)

- Battery Test

- Charging System

- Electric Starting System

- Pinion Clearance

Troubleshooting

- Tests and Calibration

- Code-based Troubleshooting

Wiring Schematics (Foldout and Collage sizes)

On-Highway Engines Electronic PTO Installation and Application Guide

General Torque Specifications for All Caterpillar Products