Caterpillar C15 SDP Truck Engine Complete Service Manual

$129.99

Covers: Caterpillar C15 Truck Diesel Engine

- SDP serial number prefix

- Please contact us with your engine serial number if you have compatibility questions.

Pages: 2,173

Format: PDF files (zipped)

File size: 68mb

Compatibility: Windows/Mac computers

Notes: Bookmarked, searchable, printable, instant download

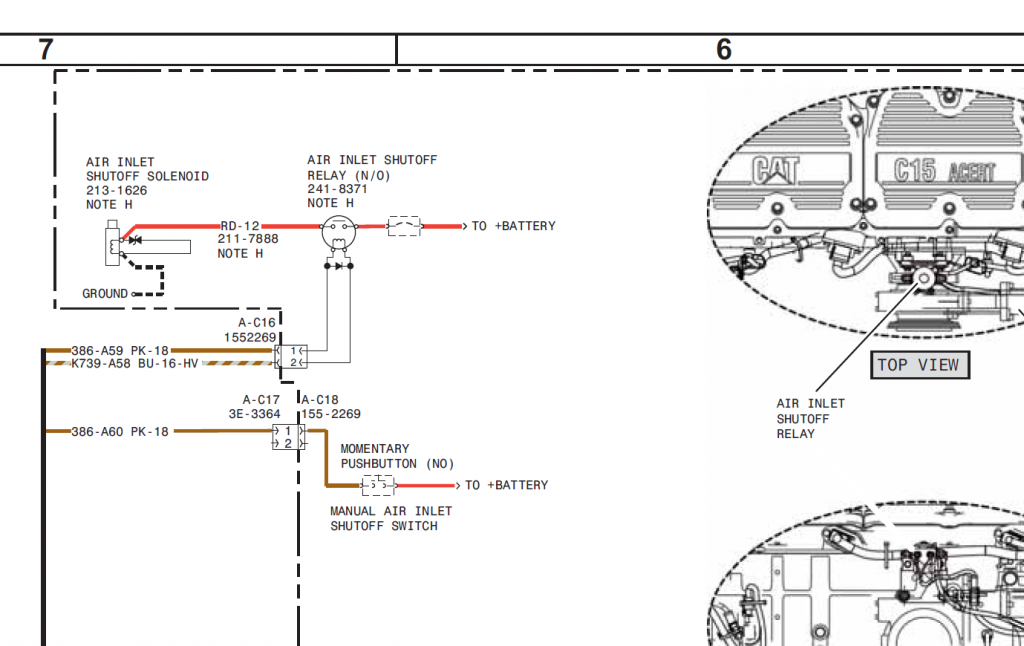

The Caterpillar C15 SDP Truck Engine Complete Service Manual set contains operating information, specifications, wiring schematics, disassembly and assembly procedures, testing and adjusting procedures and troubleshooting steps for the C15 SDP truck diesel engine. Whether you are servicing, troubleshooting or overhauling the engine, this set of manuals is recommended to accurately and safely perform the job according to the manufacturer’s standards. View the service manual on your computer or print off pages as needed. Over 2,100 total pages of engine service information is included.

Includes 11 PDF manuals in one download.

Topics:

- Caterpillar C15 SDP Complete Engine Specifications

- Engine Torque Values

- Engine Operation and Maintenance Manual

- Engine Systems Operation Manual

- Engine Disassembly and Assembly Manual

- Fuel System

- Cooling System

- Lubrication System

- Turbocharger

- Air Intake and Exhaust

- Engine Testing and Adjusting Manual

- Engine Troubleshooting Manual (With and Without Code)

- Printable Caterpillar Electrical Schematics (Wiring Diagrams) For ALL SDP Serial Numbers

- Cat On-Highway Engines Electronic PTO Service Manual

- And Much More…

Sample pages: