Case NH 445/M2, 445T/M2, 668T/M2 Tier II Engine Service Repair Manual

$38.99

Covers: Case New Holland 445/M2, 445T/M2, 668T/M2 Tier II Engine

Pages: 180

Format: PDF

File size: 12mb

Works with: Windows/Mac/Tablet

Notes: Please contact us if you have compatibility questions

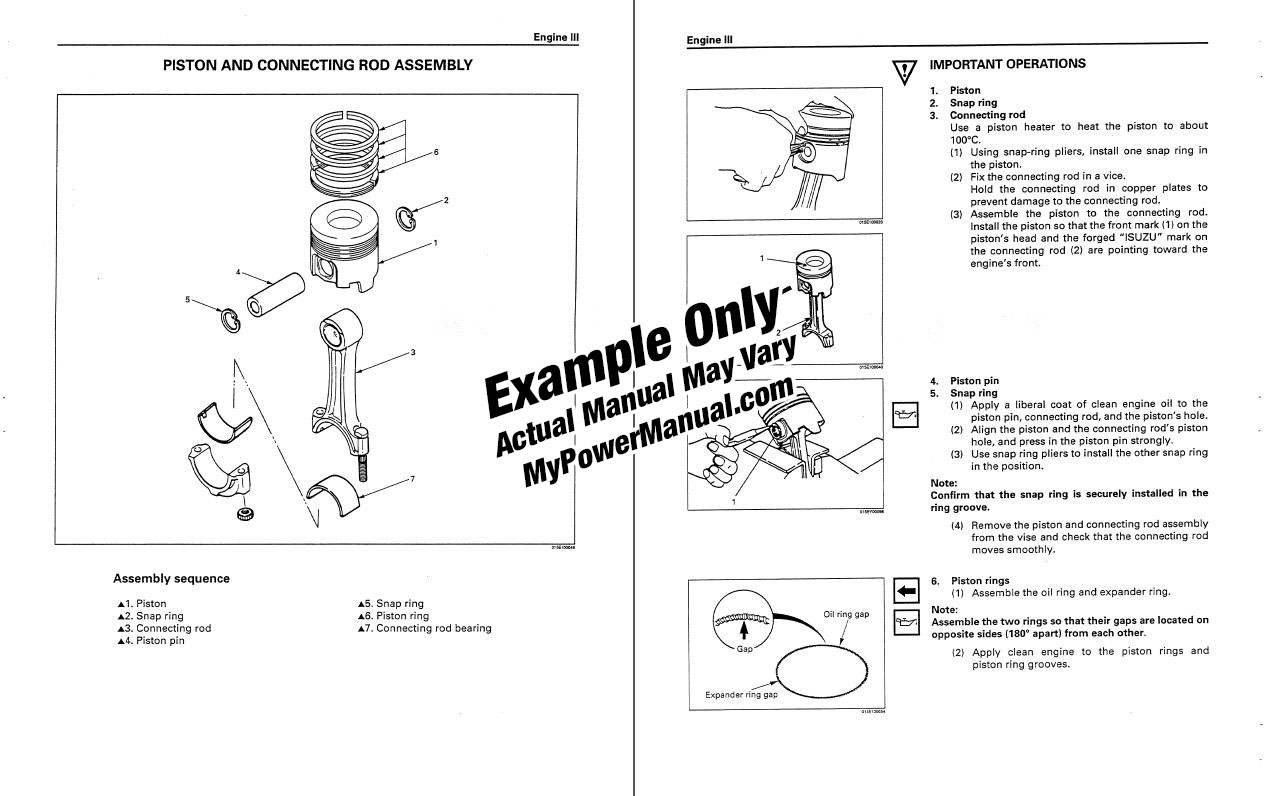

This service manual contains the necessary technical information to carry out repair and overhaul on CNH 445/M2, 445T/M2, 668T/M2 Tier II engines, necessary tools to carry out those operations and information on service standard, on procedures for connection, disconnection and disassembly and assembly of parts.

Topics in the Case New Holland 445/M2, 445T/M2, 668T/M2 Tier II Engine Service Manual:

- General information

- Feed

- Duty – Industrial applications

- Mechanical Injection Engines

- Overhaul and Technical Specifications

- Equipment

- Installation guidelines

- Safety instructions